Maintenance

Complete inspections of the forklift truck prevents faults previously and extends an usable period of the truck, hours shown below are based on 8-hour operation per a day and 200-hour operation per a month.

Do the detailed record well after checking and keep the record for 3 years at least.

CAUTION:

·Only trained and authorized serviceman shall be permitted to service the truck.

·Daily servicing,weekly servicing and monthly servicing are all could be done by the operator.

General Rules on Inspection

Use genuine parts only.

Use genuine or recommended oil only.

Clean oil fillers and grease fittings with a brush or waste cloth before adding oil or greasing.

Oil level check and addition of oil should be made with the truck parked on a level surface.

Preventive maintenance services should be done in an orderly manner and due care taken not to injure yourself.

If unavoidable to work under the raised forks or attachment, use a stable support to prevent the forks and inner mast from falling down.

If any damage or fault is found, the matter should be reported to your supervisor and the truck should not be operated until corrected.

Instructions for maintenance

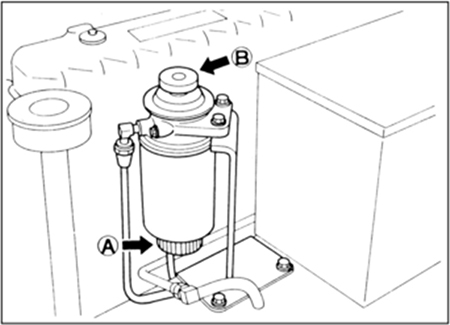

Water discharge from sedimenter.

DIESEL

When sedimentor indicator lights up:

» Stop the engine, loosen the drain plug by turning 4 to 5 turns (A) and press the priming pump(B).Continue pressing the priming pump (B)until water is entirely discharged through the sedimentor.

» Fasten the drain plug and press the priming pump several times to see that there is no fuel leakage from the plug.

» Start the engine to confirm that the indicator does not light up.

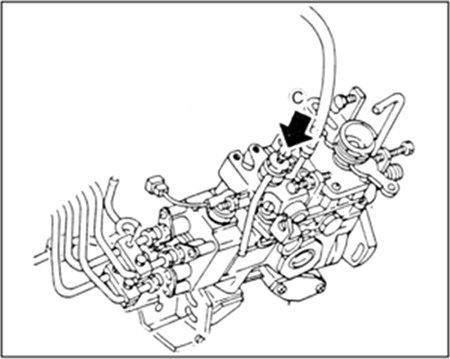

When air-bleeding fuel system.

DIESEL

» Stop the engine and loosen the bleed plug(C) on the injection pump.

» Press the priming pump until fuel coming through the bleed plug contains no bubble.

» Fasten the bleed plug to confirm that there is no fuel leakage from the plug screw.

Replacing fuse

» The fuse protects the electric system against overcurrent.Use the specific ampere rating of fuse.Check to see that the components in each circuit are operating properly.If every component in a circuit is not functioning, it is an indication that the corresponding fuse is blown out.Replace the blown fuse with a spare fuse of the same capacity.If a part of the components in the circuit does not function properly,it is suspected that a bulb has burnt out.The burnt bulb should be replaced with new one of the same capacity.

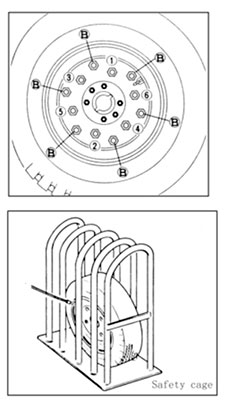

Replacing or repairing tire

» Prepare tools and jack necessary for replacing or repairing tires.

FRONT WHEEL

» Stop the truck on a level,hard surface and shut down the engine.All loads should be unloaded from the truck.

» Apply the parking brake and block the wheels.Put the jack under the truck frame.

» Jack up the truck to the extent that the tire still remains on the ground.Loosen the hub nuts.Do not remove them.

» Again jack up the truck until the tire leaves off the ground.Remove the hub nuts,and detach the wheel.

» The wheel should be reinstalled in the reverse order:The hub nuts should be tightened in the diagonal order evenly.

» After reinstallation, check the tire for proper inflation pressure.

» Tire inflation pressure ≅ 700kPa.

REAR WHEEL

» Use the same manner as with the front wheel tire repair or replacement except for the position of the jack which goes under the counterweight.