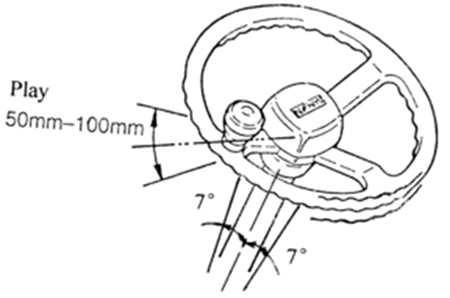

Servicing

Complete inspections of the forklift truck prevents faults previously and extends an usable period of the truck. Hours shown below are based on 8-hour operation per a day and 200-hour operation per a month.

CAUTION:

Only trained and authorized serviceman shall be permitted to service the truck.

Inspection prior to operation, inspection of after operation, weekly servicing and monthly servicing are all could be done by the operator.

Heli pure components and parts are requested to be used in addition to the spare parts of original engine manufacturer.

Instructions for maintenance

Inspection Prior to Operation

Inspecting the truck prior to operation should be done for safety operation and keep good condition of the truck. This is a duty in law. When there is fault, contact the sale apartment of our company.

CAUTION:

A small fault could cause a serious accident. Do not operate or move the truck prior to finishing repair works and inspect.

Inspecting trucks should be made on a flat floor.

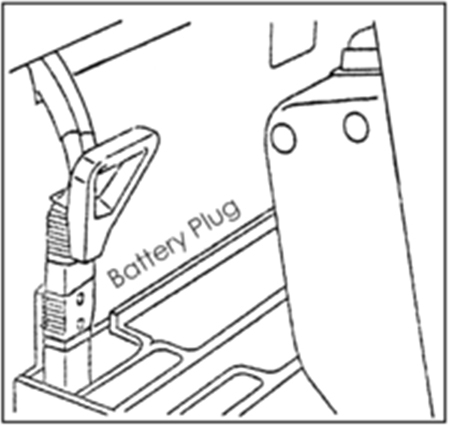

Trucks in need of inspection to electrical system shall have the key switch turned off and the battery disconnected prior to such inspection.

The improper dealing with the waste oil, For example pipe it to a drain or the soil or burn the waste oil, will pollute water, soil and air. It is banned by law.

Inspection procedure

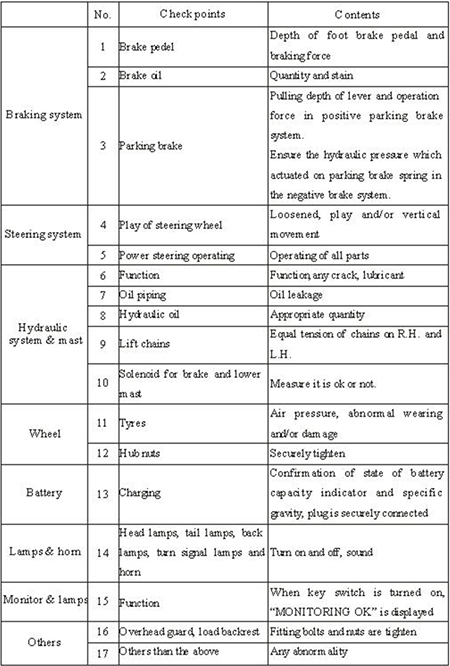

CHECK OF FOOT BRAKE PEDAL

» Check performance of brake and make sure that it is over 50mm from the floor plate when depressing the brake pedal fully. Proper braking distance without a load is about 2.5m.

CHECK OF FOOT BRAKE PEDAL

CAUTION:

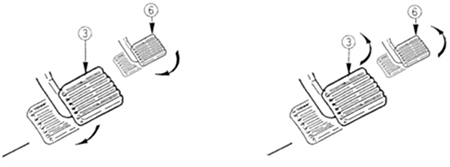

» Remove the cap of brake oil tank and check the quantity and condition of the brake oil.

CHECK OF PARKING BRAKE LEVER

» Pulling the parking lever and to see:

Suitable pulling stroke

Braking force

Damaged parts

Lever operation force(standard 17-22kg)is suitable for operator or not.

Adjustment should be done by a screw which located on the top of lever.

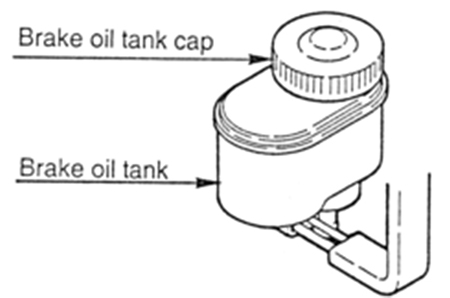

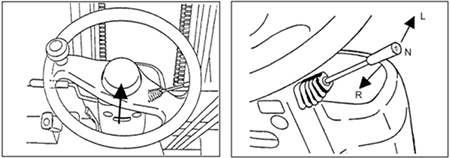

CHECK OF PLAY OF STEERING WHEEL

» Turn the steering wheel clockwise and counterclockwise lightly and check to see if there is play. Appropriate play is 50-100mm. The steering wheel can be adjusted forward and backward for a certain angle.

CHECK OF POWER STEERING FUNCTION

» Turn the steering wheel to clockwise and counterclockwise, check the power steering operation.

CHECK OF FUNCTION

» Check if lifting and tilting operation are smooth.

CHECK OF OIL PIPING

» Check for any oil leakage from the lift cylinders, tilt cylinders and oil piping.

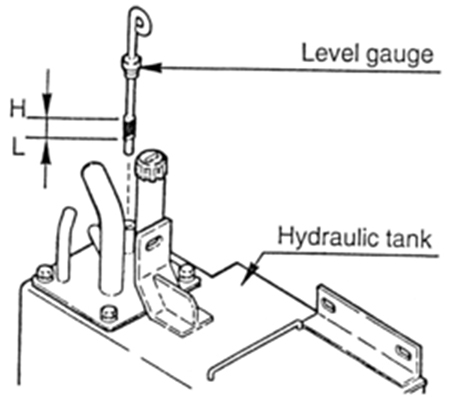

CHECK OF HYDRAULIC OIL

» Check oil lever,using the oil level dip stick with the forks lowered on the floor. Appropriate oil quantity is within the range of H to L.

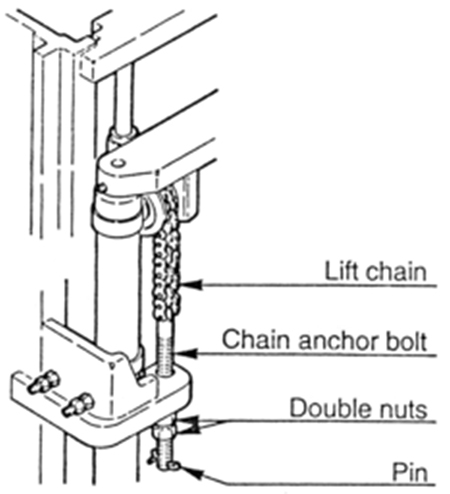

CHECK OF LIFT CHAINS

» Lift up forks by 200-300mm above the floor, and make sure lift chains are equivalent in tension.

» Check the finger bar if it does not decline either to right or left side. If the tension is different, adjust using the chain anchor bolts.

CAUTION:

» After having adjusted, tighten up the double nuts securely.

CHECK OF TYRES (PNEUMATIC TYRES)

» Measure the air pressure by using the tyre gauge after removing the cap. After checking air pressure, make sure air does not leak from the vale before replacing the cap.

CAUTION:

» Air pressure for forklift truck is higher than a normal car, do not raise the pressure over the appointed pressure.

» Check of tyres(solid tyres)

» Check the tyre and it’s side face if there is any damage or craze. Check the rim if there is any distortion or damage.

CHECK OF HUB NUTS

» Check if the hub nuts are loosen by

tightening them with a box wrench.

CHECK OF CHARGING

» Measure the specific gravity of battery. When they show 1.275-1.285 at 30℃ conversion, the battery is full charged. And check the terminals which are loosen and the cable which is damaged.

CHECK OF HEAD LAMPS

» Turn signal lamps and horn.

» Check if lamps turn on.

» Check if horn sounds.

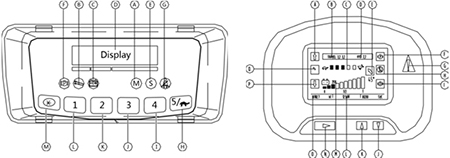

CHECK OF METER

» The meter will be display as shown in the figure after the key switch is on for several seconds normally.

CHECK OF OVERHEAD GUARD AND LOAD BACKREST

» Check if any fitting bolts or nuts are not loosen.

OTHERS

Check for any other abnormality.

CAUTION:

» Be sure to turn off the key switch and disconnect the battery plug while checking electric system except turning on the lamps and checking operation.

Inspection After Operation

» Deterioration or leakage at all parts.

» Deformed, distorted, worn or cracked members.

» Apply grease in accordance with condition.

» Lift forks to the maximum lift height of the truck several times after operation.(When the maximum lift height was not used in the day’s operation, the operation provides oil to cover at internal cylinders for preventing rust.)

» Verify an abnormal part which observed any defects during operation.

CAUTION:

A small fault could cause a serious accident. Do not operate or move the truck prior to finishing repair works and inspect.

WEEKLY (50-HOUR) SERVICING

» Inspect the following servicing in addition to the inspection prior to operation.

CAUTION:

» Be sure to disconnect the battery plug when inspecting the electrical system.

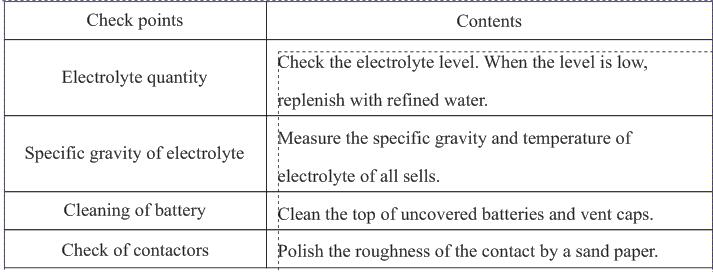

» Check for quantity of electrolyte

CAUTION:

» After completed the replenishment, close the vent caps securely. ·Do not replenish over the water. Flooding could make an electric shock.

» Check for specific gravity of electrolyte Measure the quantity and specific gravity of all cells. Normal:When all sell’s specific gravity are the same figure as converted figure at 30, it is normal. Abnormal:When the specific gravity is less than 0.05 from the average figure of others, it is abnormal.

» Cleaning of battery Keep dry condition by wiping off with a wet cotton cloth to protect corrosion at the connecting area of top batteries.

CAUTION:

» Cleaning of the battery should be done before charging. ·Wear rubber gloves and boots to prevent a electrical shock. ·Handle the battery plug not to touch water. The inside of vent caps will be stained. Clean them as following procedures.

Monthly(200-hour) Servicing

» Carry out the following service besides the weekly(50-hour) maintenance.

» As a result of inspection, when adjustment or replacement should be necessary, call serviceman of our company.(Record of monthly maintenance should be kept.)

Every Three-month(600-hour)Servicing

» At the same time with the every three month (600-hour) servicing, repeat the sequence of monthly (200-hour) servicing. When adjustment or replacement of part should be necessary, call qualified serviceman of our company.

Semiannually(1200-hour) Servicing

» At the same time with the semiannually (1200-hour) servicing, repeat the sequence of every three monthly (600-hour)servicing. When adjustment or replacement of part should be necessary, call qualified serviceman of our company.